To cement mill main motor bearing burning accident analysis and processing

Article source: Secretary Jia Qing editor: Wannan motor

[Wannan motor introduction]: a cement plant cement mill main motor model YRKK800-8, power 2500kw and the bearing Babbitt, the material synthesized by the tin, lead, antimony, copper and other metal, with soft texture of the low temperature characteristics, Babbitt maximum use temperature is 100 DEG C, for the protection of the bearing and in the control of bearing temperature protection limit set the value of 63 DEG, exceeds the set value, the DCS control chain to stop jumping mill main motor. Grinding the main motor lubricating oil station matching 2 sets of pressure switches, pressure were set to 0.12MPa and 0.2MPa. Oil station oil pressure normal value of about 0.25 MPa, if the fuel supply pressure is less than 0.2MPa, start standby pump to the oil pressure to meet the main motor bearing lubrication demand; if the oil pressure below 0.12mpa, lubrication system in the presence of faults, the oil pressure signal chain mill main motor jump stop, to avoid bearing high temperature liner burnt.

1, fault phenomenon

January 7, 2015, the plant No. 2 in the control room of the cement mill control room due to DCS control power failure trip, resulting in cement grinding system DO signal is lost, resulting in a total of 2 cement grinding system all low voltage equipment jump stop. Personnel inspection found mill main motor is still in operation, then immediately press the emergency stop button field. After a sudden stop by electrical inspectors found the main motor rotor journal wear serious, before and after the bearing are due to high temperature and burn. DCS system fault in thin oil station jump stop, the oil pressure below 0.12mpa and no chain jump stop main motor, over temperature of the bearing bush nor chain jump stop main motor, which is caused by the main motor rotor shaft neck wear, the root cause of the liner burnt.

2, fault reason analysis

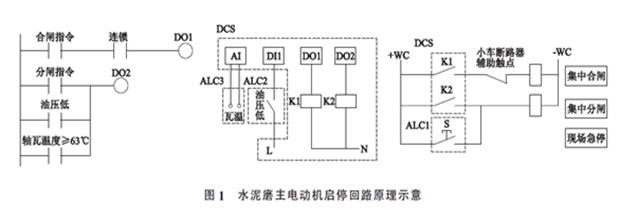

Cement mill main motor for high voltage electrical equipment, its start and stop circuit principle diagram 1.

As shown in Figure 1, from DCS system drives the relay K1 and K2 are pulse trigger closing and tripping two coil to realize the main motor's start and stop. Distributed control system (DCS) after the loss of electricity, concentrated brake command cannot be operation of a main motor is stopped by the K2; and on the other hand, oil pressure ultra low and bearing temperature chain jump stop signal are also by DCs output control brake coil, DCS fault was also unable to trigger the car circuit breaker tripping, resulting in protection system failure, equipment failure can not be parking.

3, fault treatment

Mill main motor sub gate circuit is controlled by the DCS system. In the design, it is not fully considered the impact of DCS failure on the device, while the hard chain can solve this problem. Hard wiring, the lubricating oil lubricating station low oil pressure signal leads to the mill main motor of high voltage switchgear tripping circuit can be, but the lubrication thin oil station set up at the scene, far from the scene of high voltage switch cabinet, cable direct laying time-consuming laborious and cable costs high. According to the field situation, the electrical maintenance personnel decide to use the distance of the emergency stop button box of the oil station and the main motor to send the signals in parallel to the high voltage cabinet. Bearing temperature signal acquisition is for analog, so not to transform. After the transformation of control principle diagram 2.

As shown in Figure 2, the of the intermediate relay is added to the control box ALC2 in the lubricating oil station, and the soft and hard interlock control of the main motor is realized by K4 and K3. The soft control of K3 auxiliary contacts are connected to the DCS cabinet Di point equipment tripping coil, K4 auxiliary contacts are connected in parallel to the side of the machine button box alc1 directly achieve tripping coil hard control in the trip circuit of the equipment, after the transformation of test drill success gate. Then, respectively for grinding thin oil station, grinding tail thin oil station and the main reducer dilute oil station for the same kind of reform and low oil pressure signals in parallel to figure 2 gate circuit of the oil station, so that any oil station fault can jump in time to stop the main motor and reliability through soft chains and hard chain double insurance, an increase of the mill main motor fault stop jumping.

4, the end of the language

The accident exposed hidden trouble of equipment in the design, in the design should pay special attention to the different voltage levels of equipment between chain correlation, more thinking in different fault conditions caused by the equipment, timely detection of equipment operation and parking control dead, perfect design, maintenance equipment, good safety management and enterprise's safety production.